Solar power storage could get a whole lot cheaper with used electric vehicle batteries

A research team from Utah State University has developed technology to utilize retired EV batteries for solar power storage, which it said could reduce costs by up to 50%.

” data-credit=”Image: Utah State University”>

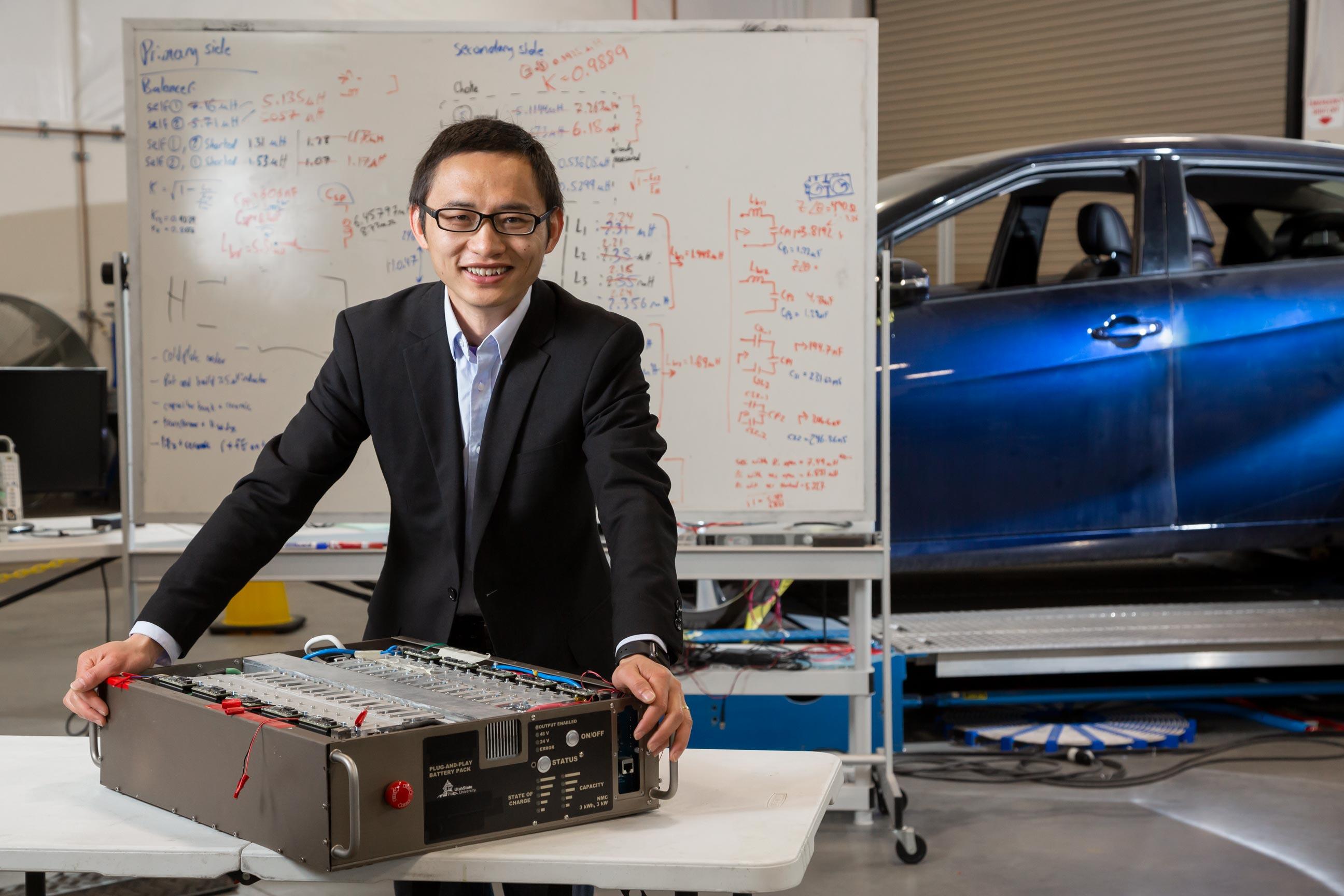

Assistant professor of electrical and computer engineering Hongjie Wang’s team has developed technology to keep used EV batteries out of landfills and recycling centers by putting them back to work storing solar energy.

Image: Utah State University

Electric vehicles have the potential to drive down carbon emissions, but they don’t come without problems, and battery waste is particularly serious one. Luckily, a team of researchers from Utah State University have developed technology to turn retired EV batteries into solar energy storage units.

The team, headed by USU assistant professor of electrical and computer engineering Hongjie Wang, developed its EV battery waste solution in partnership with Maryland-based security research firm Dream Team, with the ultimate goal of making solar power more affordable, and therefore more viable for widespread use.

Citing the low cost of retired EV batteries and active life-balancing technologies developed by the USU team, Wang said that the target is to reduce the cost of solar energy storage by 50%.

SEE: The CIO’s guide to quantum computing (free PDF) (TechRepublic)

“There’s still a lot of capacity there, but it’s not preferred for the EV application,” said Wang. “We can use that remaining capacity for other applications. With solar energy, you don’t have a mileage problem—you just need to provide enough energy storage.”

Electric vehicle battery waste is a growing concern among scientists and environmental advocates. According to the BBC, each EV battery is made up of hundreds of lithium-ion cells, each of which has to be dismantled in order to be recycled. Add to that the tendency for lithium-ion cells to explode if an error is made in the dismantling process and you have an expensive, risky process that Birmingham University Faraday Institution research fellow Gavin Harper said invites trouble.

“In some markets, such as China, health and safety regulation and environmental regulation is much more lax, and working conditions wouldn’t be accepted in a Western context,” Harper told the BBC.

The Union of Concerned Scientists USA said in a report on EV battery waste that there are currently fewer than a dozen facilities in the world actively recycling electric vehicle batteries. UCSUSA also cites data suggesting that production costs for EV batteries are also environmentally high, with manufacturing contributing 14% to 24% of the global warming emissions for an electric vehicle. By contrast, refining crude oil into automotive gasoline is responsible for 24% of the fuel’s overall greenhouse gas emissions.

In short, the more life that can be squeezed out of an electric vehicle battery, the better, and retired EV batteries aren’t short on capacity. EV batteries are typically replaced while still having up to 85% of their original capacity—more than enough for use in solar energy storage.

SEE: Hiring Kit: Video Game Designer (TechRepublic Premium)

Wang, along with his team made up of people including electrical and computer engineering professor Regan Zane and doctoral students Marium Rasheed and Mohamed Kamel, developed their new technology as part of the American-Made Solar Prize competition sponsored by the U.S. Department of Energy and the National Renewable Energy Laboratory.

So far, the USU team has made it through to a pool of 10 finalists out of 121 teams. Thus far the team has won $225,000 in cash and voucher funding, and winning the contest could net them an additional $575,000 for key technology production.